|

| |

Dual-axis Pitch and Roll Stage

|

|

Home

>

Motorized Yaw, Pitch and Roll Stages

|

|

|

|

The PR15-60-01 (pictured) is driven by stepper motors and the PR10-60-02 is driven by brushless servo motors with quadrature incremental optical encoders.

The Pitch axis (lower stage) is a high precision goniometer stage which features preloaded cross roller guides and a high ratio worm drive for smooth motion over a range of travel of +/- 15 Degrees. It has a typical accuracy of 0.05 Degrees and repeatability of +/- 0.01 Degrees.

Additionally, this axis has end-of-travel limit switches.

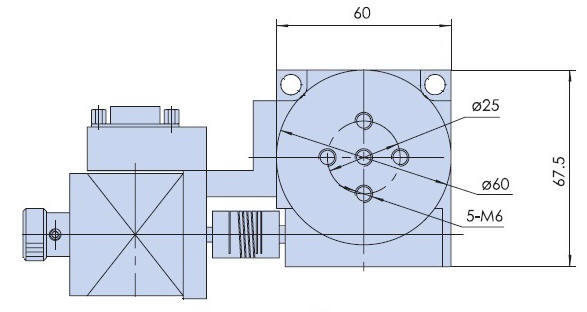

The 60 mm diameter Roll axis (upper stage) has a 90:1 gear ratio for smooth motion and has a precise pattern of threaded holes for fixtures or tooling. This axis has an accuracy of 0.05 Degrees and repeatability of +/- 0.01 Degrees. The Roll axis has a Home signal for initialization.

Each axis features a calibrated scale to visually display the angle. The maximum speed with stepper motors is 14 Degrees/second and 45 Degrees/second with servo motors.

The knobs of the stepper motors can be replaced with optional optical encoders for position verification.

The resolution of the PR10-60-01 stepper motor driven duel-axis stage depends on the resolution of the step motor driver resolution or the optical encoder if a servo motor is used. A resolution of 0.001 Degrees equivalent to 3.6 arc-sec can be achieved using a10 micro-steps per step stepper motor driver or an encoder with a resolution of 500 cycles per revolution.

The PR15-60-02 that features servo motors and optical quadrature encoders are used for very precise closed loop operation and greater speeds.

The Dual-axis Pitch and Roll Stages require a

Motion Controller

that can be ordered as a complete plug-and-play system with joystick and keypad.

|

|

|

|

Specifications

| |

PR15-60

|

|

Total Weight

|

3.0 kg (6.6 lb)

|

|

Load Capacity

|

4.0 kg (8.8 lb)

|

|

Base Material

|

Aluminum Alloy

|

|

Surface Treatment

|

Black Anodized

|

|

|

| |

|

|

DB-9 Male Connector

|

|

Stepper Motor

|

|

Pin Assignment and Description

|

|

1

|

+5 VDC

|

|

2

|

CCW Limit Switch

, Open Collector, Normally Open, Needs Pull up Resistor

(Pitch Axis)

|

|

3

|

CW Limit Switch

, Open Collector, Normally Open, Needs Pull up Resistor

|

|

4

|

Common

(Pitch Axis)

|

|

5

|

HOME Switch, Open Collector, Normally Open, Needs 1K Pull up Resistor (Roll Axis)

|

|

6

|

Stepper Motor Phase A+ |

| 7 |

Stepper Motor Phase A- |

| 8 |

Stepper Motor Phase B+ |

| 9 |

Stepper Motor Phase B- |

| |

|

| |

Roll

(Rotary) Axis

|

|

Structure Description

|

| Gear Ratio |

1 Degrees

(stage) : 90

Degrees

(motor)

|

| Drive Mechanism |

Worm Gear

|

| Travel Guide |

Bearing |

| Stage Diameter |

60 mm |

|

Typical Accuracy

|

|

Resolution

|

0.001 Degrees = 3.6 arcsec (10 Micro-steps per Step Motor Driver in use)

|

|

Repeatability

|

+/-0.01 Degrees

|

|

Positional Accuracy

|

0.05 Degrees

|

|

Maximum Speed with Stepper Motor

|

30 Degrees per second |

|

Maximum Speed with Servo Motor

|

45 Degrees per second |

|

Typical Stepper Motor Phase Current

|

1

.0 Amp

|

|

|

Pitch (Goniometer) Axis

|

|

Structure Description

|

Range of Travel |

+/-15 degrees |

|

Gear Ratio |

1 Degrees (stage) : 252 Degrees (motor)

|

|

Height of Rotation Stage |

50 mm+/-0.2 mm |

|

Drive Mechanism |

Worm Gear |

|

Travel Guide

|

Crossed-roller Guide |

|

Rotation Center Deflection Accuracy

|

0.03 mm

|

|

Typical Accuracy

|

|

Resolution

|

0.001 Degrees = 3.6 arcsec (10 Micro-steps per Step Motor Driver in use)

|

|

Repeatability

|

+/-0.01 Degrees

|

|

Positional Accuracy

|

0.05 Degrees

|

|

Maximum Speed with Stepper Motor

|

14 Degrees per second |

|

Maximum Speed with Servo Motor

|

45 Degrees per second |

|

Typical Stepper Motor Phase Current

|

1

.0 Amp

|

|

|

|

Stepper Motor Driven Mechanical Drawing (Roll Table)

|

Ordering Information

|

Part No.

|

Description

|

Amount

|

|

PR

10-60-01

|

Dual-axis Stepper Motor Driven Yaw and Pitch Stage

,

Table Diameter: 60 mm

|

Click to Get a Quote

|

|

PR

10-60-02

|

Dual-axis

Three Phase Brushless Servo Motor with Quadrature Incremental Optical Encoder Driven

Yaw and Pitch Stage,

Table

Diameter: 60 mm

|

Click to Get a Quote

|

|

PR

10-60-03

|

Dual-axis DC Brush Servo Motor with Quadrature Incremental

Optical Encoder Driven Yaw and Pitch Stage, Table Diameter: 60

mm

|

Click to Get a Quote

|

|

PR

10-60-04

|

Dual-axis Stepper Motor Driven Yaw and Pitch Stage

with 500 Cycle per

Revolution

Quadrature Optical Encoder

,

Table Diameter: 60 mm

|

Click to Get a Quote

|

Related Products

|